Airborne Disinfection

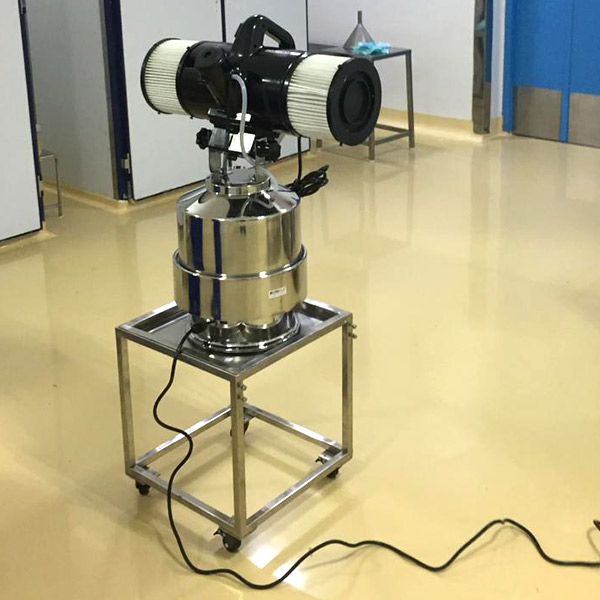

Yantra 09 Automated + Rotoplus 09 is an advanced airborne disinfection system, when used with H2O2 based disinfectants, offers highly effective bio decontamination treatment. It produces oxidizing free radicals out of H₂O₂-based disinfectants and dispenses high-volume ultra-fine aerosol fog that disperses like gas, with complete 3D coverage contact for maximum microbial kill.

When mounted on top of Rotoplus 09 turntable (360 Deg rotating turntable) results into maximum coverage, uniform disinfection of small to large areas with reproducible results. The high-powered system reduces treatment time significantly, with constant treatment of multiple rooms. The ultra-thin film deposition of disinfectant provides maximum bio decontamination without unwanted wetness, making it ideal choice for sterile areas of pharmaceutical companies, Operation theatres, Laboratory environments.

Suitable for hospitals, pharmaceutical plants, laboratories, sterile areas & aseptic areas this high-performance system guarantees the highest level of hygiene, infection control & bio decontamination control.

- Generates vapour of oxidizing free radicals out of H₂O₂ disinfectants

- Gas-like diffusion

- High volume of aerosol output

- Large area coverage with complete coverage accuracy

- Shorter treatment time & treats more rooms without stopping

- 3D aerosol contact, very thin film deposition

- Sturdier, least maintenance & long lasting

- Complete kill: Virus/Bacteria/Spores

- Dry aerosol fog of oxidizing free radicals out of H₂O₂ disinfectants

- Gas-like diffusion with high volume output

- 3D contact with large area coverage accuracy

- Very thin film deposition, no excessive wetness

- Treats larger area without stopping, continuous running

- Space treatment: Up to 16000 Cuft

- Time for 8000 Cuft: 35 minutes @ 200ml/1000 Cuft dosage

- Sturdier, least maintenance & long lasting

- Enter the room the sizes (Length x Width X Height) & set the volume of room under the treatment.

- Total 30 room size details & application dosage can be saved for precise treatment.

- Select required application dosage (200ml/1000cuft or more,)

- Pour required solution advised by the machine.

- Delayed start to leave the premises & Auto OFF operations

- Room size saving facilitates ease of operation.

- Hospitals: Operation theatres, ICUs

- Pharmaceutical Plants: Sterile production areas, aseptic areas

- Laboratories: Microbiology, Tissue culture, Animal Houses, Hatcheries, Sericulture.

- Food processing: dairy industry, Nutraceutical manufacturing, Ayurvedic medicine production

- Disinfection: treatment again disease outbreak & Epidemic.

- Throw 5Oft, 28ft. height

- Treatment of 1000cuft space: 200-400ml. disinfectant solutions.

- Automatic dosing, 45ml/minute flow rate,

- Motor Housing: Special Cooling vents for air cooling of turbo motor.

- Pre filters and cartridge type Main filters : Easily removable and Cleanable

- Solution Tank Assembly set : 9 Litres, SS Gr. 316.

- Ultra low Disinfectant solution consumption 200ml/1000cuft / 7ml/m3

- Cartridge type filters: Easily removable and cleanable

- Generates vapour of oxidizing free radicals out of H2o2 disinfectants.

- Gas like diffusion.

- High volume of aerosol output.

- Large area coverage with complete coverage accuracy.

- Shorter treatment time & treats more rooms without stopping.

- 3D aerosol contact, very thin film deposition.

- Sturdier, least maintenance & long lasting.

- Complete kill: Virus /Bacteria/ Spores.

- Dry aerosol fog of oxidizing free radicals out of H2o2 disinfectants.

- Gas like diffusion with high volume output

- 3D contact with Large area coverage accuracy

- Very thin film deposition, no excessive wetness.

- Treats larger area without stopping, continuous running

- Space treatment: Up to 16000 Cuft,

- Time for 8000cuft: 35 minute @ 200ml/1000cuft dosage.

- Sturdier, least maintenance & long lasting.

![]() Hospitals: Operation theatres, ICUs

Hospitals: Operation theatres, ICUs![]() Pharmaceutical Plants: Sterile production areas, aseptic areas

Pharmaceutical Plants: Sterile production areas, aseptic areas![]() Laboratories: Microbiology, Tissue culture, Animal Houses, Hatcheries, Sericulture.

Laboratories: Microbiology, Tissue culture, Animal Houses, Hatcheries, Sericulture.![]() Food processing: dairy industry, Nutraceutical manufacturing, Ayurvedic medicine production

Food processing: dairy industry, Nutraceutical manufacturing, Ayurvedic medicine production![]() Disinfection: treatment again disease outbreak & Epidemic.

Disinfection: treatment again disease outbreak & Epidemic.

- Throw 5Oft, 28ft. height

- Treatment of 1000cuft space: 200-400ml. disinfectant solutions.

- Automatic dosing, 45ml/minute flow rate,

- Motor Housing: Special Cooling vents for air cooling of turbo motor.

- Pre filters and cartridge type Main filters : Easily removable and Cleanable

- Solution Tank Assembly: 9 Liter, SS Gr. 316.

- Ultra low Disinfectant solution consumption 200ml/1000cuft / 7ml/m3

- Cartridge type filters: Easily removable and cleanable

![]() Hospitals: Operation Theatres, ICUs

Hospitals: Operation Theatres, ICUs![]() Pharmaceutical Plants: Sterile production areas.

Pharmaceutical Plants: Sterile production areas.![]() Laboratories: Tissue Culture, R&D centres.

Laboratories: Tissue Culture, R&D centres.![]() Food Processing, Animal Houses, Hatcheries

Food Processing, Animal Houses, Hatcheries![]() Disinfection Treatment again Disease Epidemic

Disinfection Treatment again Disease Epidemic

- Throw 5Oft, 28ft. height

- Treatment of 1000cuft space: 200-400ml. disinfectant solutions.

- Automatic dosing, 45ml/minute flow rate,

- Motor Housing: Special Cooling vents for air cooling of turbo motor.

- Pre filters and cartridge type Main filters : Easily removable and Cleanable

- Solution Tank Assembly: 9 Liter, SS Gr. 316.

- Ultra low Disinfectant solution consumption 200ml/1000cuft / 7ml/m3

- Cartridge type filters: Easily removable and cleanable

![]() Hospitals: Operation Theatres, ICUs

Hospitals: Operation Theatres, ICUs![]() Pharmaceutical Plants: Sterile production areas.

Pharmaceutical Plants: Sterile production areas.![]() Laboratories: Tissue Culture, R&D centres.

Laboratories: Tissue Culture, R&D centres.![]() Food Processing, Animal Houses, Hatcheries

Food Processing, Animal Houses, Hatcheries![]() Disinfection Treatment again Disease Epidemic

Disinfection Treatment again Disease Epidemic

- Throw 50ft, 25ft height

- Ultra low Disinfectant solution consumption: 200ml/1000cuft / 7ml/m3

- Aerosols, submicron size (non wetting)

- Accurate dosing, 35ml/minute flow rate

- Solution Tank Assembly: 5 Litre, SS304 or SS316 or Engineering plastics.

- Continuous running: 60 minutes

- Enter room size & set the volume of room under the treatment.

- Pour required solution advised by the machine.

- Delayed start to leave the premises & Auto OFF operations

- Option room size saving facilitates ease of operation.

- Hospitals: Operation Theatres, ICUs

- Pharmaceutical Plants: Sterile production areas.

- Laboratories: Microbiology, Tissue Culture, R&D centres.

- Food Processing, Animal Houses, Hatcheries

- Disinfection Treatment again Disease Epidemic

- In the fight against infections & disease outbreak, we have developed the ultimate safe, rapid & effective fumigation machine, which can be used with wide range of (H2O2 based) fogging solutions & other environment disinfectants for effective removal of spores, bacteria and the virus associated with a wide range of nosocomial pathogens.

- Used in : Operating theatres, recovery rooms, ICUs, mortuaries, general wards, ambulances, IVF facility Laboratories, clinics etc.

- Companies & labs need to ensure that their clean rooms & sterile areas are microbiologically safe at all times in order to manufacture injections, medicines, liquid orals, vaccines as well as medical devices.

- Dry Aerosol fog of H2O2 based fogging solutions generated by AEROJET AUTOMATEDis a proven & validated disinfection treatment for these areas.

- It is equally useful for disinfection of ducts and HV/AC systems.

- Facilities can range from very small rooms to large areas.

- AEROJET AUTOMATEDis an ideal choice for aerial/environment disinfection/fogging of space in production & packaging areas and fogging on inaccessible difficult to reach machinery surfaces.

- It can also be used for disinfection of water contact surfaces such as water tanks, all food contact surfaces such as food trays, vessels, jars, machinery, food storage containers etc.

- Effective sanitation of animal facilities is vital to the health of the animals. The majority of sanitizing routines are based around the manual spraying of disinfectants that takes time and effort to apply.

- Use of AEROJET AUTOMATEDensures speedy dispersion of the disinfecting aerosol fog in large & small facilities ensuring rapid & effective aerial as well as surface sanitization all around.:

- Poultries, hatcheries, kennels, stables, veterinary surgeries and animal hospitals.

- It can be used with most liquid disinfectants, giving it the advantage of use against a broad spectrum of bacteria, viruses and fungi or for the treatment of a specific entity.

Applications

Hospital

Pharmaceutical Plants

Food Processing

Laboratories

Animal House

Hatcheries